It makes work easy. The Arduino Nano Pinout connects parts well. This improves design speed. Use every pin right. That knowledge powers devices better. Connections become clear here. These tips save time. That also avoids errors. The guide keeps you creative. It works great for ideas.

What Is Arduino Pinout?

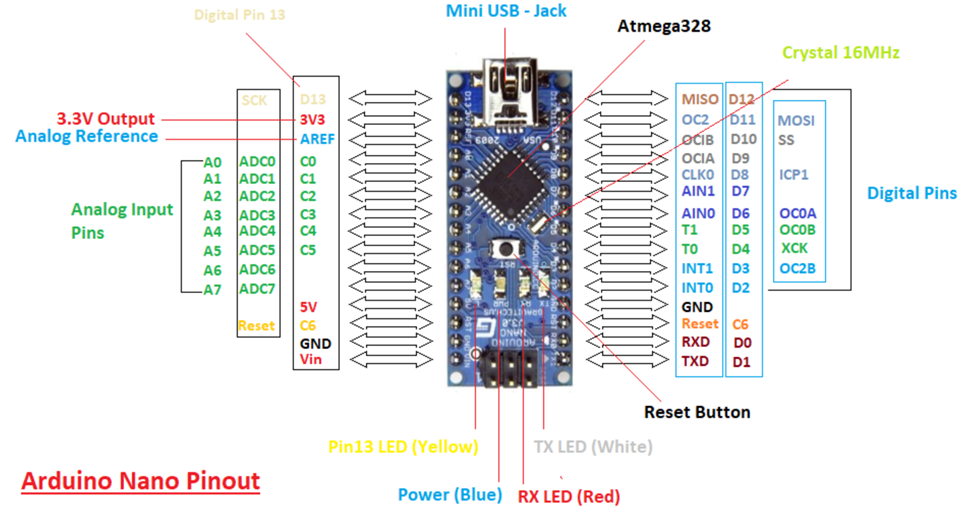

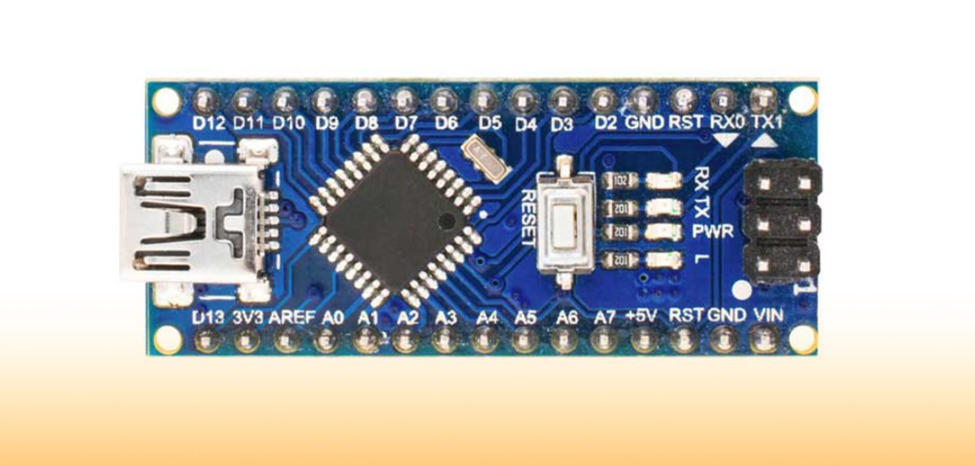

An Arduino Nano pinout shows all the pins. It helps in making circuits. D3, D5, and D9 work for PWM. A0 to A7 read sensors. VIN takes in 7-12V. 3.3V and 5V help power sensors. Use GND for grounding.

Pins are 14 digital, 8 analog. Learn how pins do jobs. Read 10-bit data from analog pins. Look for documentation often. This makes devices work. Each pin has work. Why must circuits need pins? Some wires need fewer volts.

· Why Understanding Pinouts Is Important?

It helps connect parts. Errors happen without learning. The board has 14 digital I/O pins. Eight analog pins measure signals. This uses A4/A5 for I2C and D10-D13 for SPI. D3, D5, and others manage PWM tasks. VIN takes 6-12V power. TX/RX pins send data fast. Mapping is easy when you follow this. Mistakes waste energy. Work stays simple with plans. Using pins saves stress. Data stays safe in your system.

· How Arduino Nano Pinout Differs From Other Boards?

- 30 GPIO Pins: These pins do so much. The board uses 30 GPIOs. Of those, 14 are digital. Eight are for analog input. Every pin handle 40mA. Power includes 3.3V, 5V, and VIN (6-12V). This adds I2C, SPI, UART, and RESET. They help boards reboot well. Small pins make DIY projects clean.

- 8 Analog Inputs: The board takes 8 inputs. It works with ADC of 10 bits. This reads 0V-5V levels. A4/A5 pins link I2C for data moves. Using sensors is easy here. It tracks temperature, light, and more. These parts help sensors feel things. Add inputs for cooler ideas.

- Micro USB Port: The Mini-B USB powers boards. It helps load programs fast. USB works at 5V here. It does quick transfers to PCs. Errors happen less often this way. This link skips adapters. Small boards love simple setups. That’s why users pick USB often.

- 6 PWM Outputs: PWM pins are smart here. D3, D5, D6, D9, D10, D11 help dim LEDs. The signals use 490 Hz to 980 Hz. Each pin gives 40mA output. These can move motors, lights, or actuators. Changes feel smooth, not jerky. Good outputs bring bright ideas!

Features Of Arduino Nano!

· Microcontroller

It uses ATmega328P. This is a microcontroller running at 5V. It works with a 16MHz clock. There are 14 I/O pins. Six of them support PWM. Eight analog pins are included for data. It has 32KB of flash memory.

Firmware uses 2KB SRAM. It holds 1KB EEPROM. The Arduino nano pinout is 45mm long. It supports 5V and 3.3V devices. Datasheet connections help setup. IDE integration makes it easy to use.

· Operating Voltage

This runs at 5V. It keeps voltage stable. The ATmega328P saves current. It uses 19mA. Input voltage is 7-12V. There’s a 3.3V pin for safety. A GND pin is here. VIN accepts 6-12V. Circuits stay safe.

Flow stays under limits. PWM pins handle resistors easily. Analog inputs work fine. The board stays cool.

· Digital I/O Pins

It features 14 pins. They handle schematic setups. Six are PWM-ready. GPIO is also supported. D0 and D1 use UART. SPI is for D10-D13. Pull-up resistors simplify circuits. Testing happens on D13.

The LED helps debug. Pins give 40mA max. The IDE helps developers. This supports modular designs.

· Analog Input Pins

This has 8 pins. Each reads analog data. The 10-bit ADC ensures accuracy. They read 0-1023 values. Stay below 5.5V. Pins A6 and A7 are extra. The datasheet supports design needs.

GPIO options are also available. Use analog sensors smoothly. Capacitor circuits stabilize signals. Libraries enhance performance.

· Clock Speed

It operates at 16MHz. The quartz microcontroller runs fast. Real-time tasks are handled. Timers use the clock. This supports interrupts. PWM signals are precise. Use it for servo motors.

Baud rates reach 115200. The schematic ensures solid performance. Stable firmware keeps everything optimized.

| Feature | Specification | Technical Parameters | Voltage Range | Pin Count | Speed |

| Microcontroller | ATmega328P | 8-bit, AVR architecture | 5V logic level | N/A | 16 MHz |

| Operating Voltage | 5V stabilized | Supports 7-12V input | 5V, 3.3V, GND | 3 power pins | Stable operation |

| Digital I/O Pins | 14 total | 6 PWM-enabled | 0V-5V signal range | 14 GPIO pins | Digital tasks |

| Analog Input Pins | 8 available | 10-bit ADC resolution | 0-1023 value range | 8 pins | ADC tasks |

| Clock Speed | 16 MHz | Quartz crystal oscillator | Stable timing signals | N/A | Real-time tasks |

Table on Features of Arduino Nano!

Arduino Nano Technical Specifications!

· Flash Memory

Flash Memory helps store programs. The Arduino Nano has 32 KB for tasks. It uses 2 KB for its bootloader. This leaves 30 KB for sketches. The ATmega328P microcontroller manages memory.

Diode parts help stabilize power flow. This board has 14 digital pins. It includes 6 PWM pins for LEDs. Its analog pins (A0-A7) read sensors. The 16 MHz crystal oscillator handles clock timing. Regulator circuitry keeps 5V stable. Arduino Nano pinout makes designs clear.

· SRAM

SRAM holds temporary data. The Arduino Nano uses 2 KB of it. This memory helps variables and counter operations. It manages global and dynamic storage. Digital pins (D2-D13) move data fast.

The Nano’s clock at 16 MHz helps efficiency. It uses RX/TX pins for debugging. This SRAM works for real-time tasks. Timers keep speed steady. The ATmega328P divides memory logically. Arduino Nano pinout helps optimize usage.

· EEPROM

EEPROM stores critical settings. It uses 1 KB memory, keeping data even if powered off. This memory suits small storage tasks. The 8-bit Nano handles EEPROM writes.

Analog pins A4/A5 help expand data space. It connects D0-D13 pins quickly. Crystal components stabilize its 16 MHz tasks. The 1024 bytes handle small logs well. Arduino Nano pinout aids with I/O.

· DC Current Per I/O Pin

DC power supports devices. Each Nano pin delivers 40 mA current. The A0-A7 analog pins handle signals below 5V. Regulator chips keep power steady. It connects through D2-D13 pins safely.

PWM signals control LEDs. Diodes protect against overcurrent issues. External power must fit 6-12V limits. Arduino Nano pinout simplifies sensor setups.

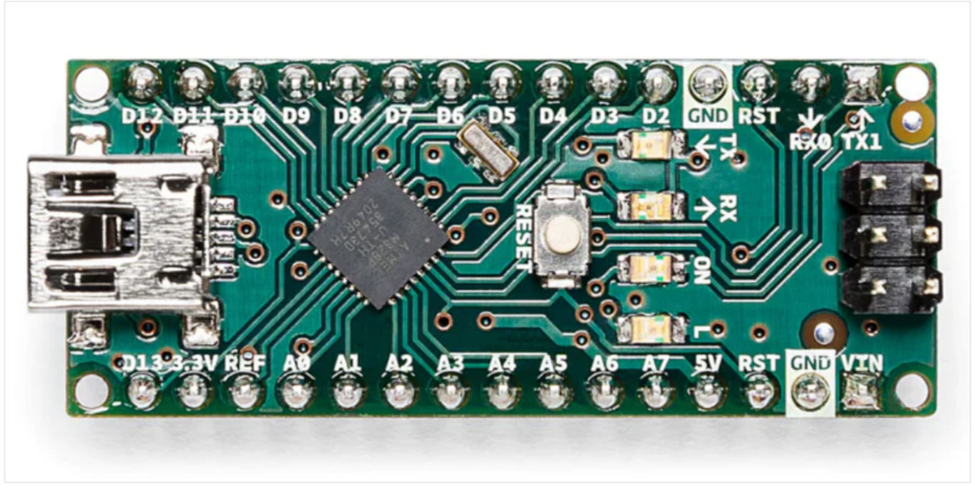

· Dimensions

Dimensions stay compact. The Arduino Nano is 45×18 mm. It weighs 7 grams. This PCB fits small designs. Its 2.54 mm pin spacing suits breadboards. The ATmega328P ensures efficiency.

LED modules fit seamlessly. USB Mini-B connects programming tools. Arduino Nano pinout helps component linking.

Arduino Nano Pinout Arrangement!

· Arduino Nano Pins

- Digital Pins: Digital pins run on 5V. Socket D0 to D13 handle signal transfers. Pins D3, D5, D6, D9, D10, D11 use PWM. Each pin draws up to 40mA. They link to PCB devices like LEDs or relays. D13 connects to an onboard LED. SPI uses pins D10, D11, D12, and D13. Connector D0 and D1 handle RX/TX at 115200bps.

- Analog Pins: Analog pins A0 to A7 sense 0-5V. They read noise or voltage with 10-bit resolution. Pins A4, A5 work for I2C at 400kHz. A6 and A7 fit extra sensors. Data stays precise using each trace.

- Power Pins: Power pins offer options. VIN handles 7-12V for boards. +5V runs regulated current. +3.3V supports low-power parts. The Arduino nano pin layout keeps energy stable. GND filters electrical noise. Filter circuits ensure smooth operations.

· ICSP Connector’s Pins

- MISO: MISO sends data. It uses a connector for easy setup. Arduino Nano pinout supports fast transfers. This pin handles up to 10Mbps. It moves signals smoothly. MISO works with SPI layout. It connects EEPROMs and sensors. Trace paths guide data. Timing ensures precision. Headers join ICs.

- VCC: VCC gives power. It links with the PCB. Stable voltage comes from this pin. Devices run smoothly. Current reaches 500mA. This pin avoids noise. The voltage filter helps protect modules. LCDs and motors need VCC. Sockets attach devices. It connects circuits safely.

- SCK: SCK syncs clocks. The pin pulses data. Arduino Nano pinout ensures harmony. SPI communication uses SCK. It drives 16MHz operations. Clock headers help timing. Robots need SCK’s traces. Devices send data easily. It fights ground errors. Multi-byte operations work here.

- MOSI: MOSI sends commands. It links master-slave devices. Speed reaches 10Mbps. Connectors support ICSP tasks. It avoids glitches. Data moves efficiently. Sensors rely on MOSI’s filter. Precise timing supports signal flow. Shift registers depend on MOSI. It aids serial projects.

- RST: RST resets controllers. It stops errors fast. ICSP header handles reset tasks. RST halts actions. Low voltage controls it. Debugging works here. Power surges won’t harm traces. Firmware gets fresh starts. This pin stabilizes operations. It prevents noise glitches.

- GND: GND ensures safety. This pin filters interference. GND protects devices. Circuits stay accurate. This creates a 0V socket. It handles ground issues. Analog sensors use GND. Arduino Nano pinout pairs GND well. Signals become stable. It avoids errors smoothly.

How To Power Arduino Nano?

· USB Connection

Connect a decoder cable. It sends 5V DC for power. This powers the Nano’s ATmega328P chip. It also enables UART communication at 115200 baud. The USB hub limits current to 500mA.

That helps prevent overload issues. It also ensures smooth serial monitoring. Check the Arduino nano pinout for TX, RX, and RESET. Always use a good cable. Avoid pulse losses in power transfer. This setup is useful for programming tasks.

· VIN Pin

The VIN pin uses 7-12V DC. This passes through the LM1117 regulator, giving 5V output. That ensures the Nano gets proper power. The regulator handles 15V max. It also stabilizes modulation for analog circuits. Review polarity for safety. A demultiplexer may improve power distribution.

Check the Arduino nano pinout to find the VIN pin. This sits near RESET. It supports higher voltage projects. Incorrect wiring damages capacitors.

· 5V Pin

Supply regulated 5V DC. This powers GPIO pins and the Nano itself. The pin skips the onboard regulator. Use a VCC source with 500mA capacity. It ensures stable operation. This powers analog pins A0-A7. Check the Nano’s pinout diagram before connecting. That prevents errors in wiring.

This method improves sampling accuracy. A multiplexer can extend GPIO control. Stable power helps the Nano’s amplifier circuits work.

· 3.3V Pin

The 3.3V pin outputs 50mA current. This power comes from the AMS1117 regulator. It suits sensors needing low voltage. That includes devices with comparator logic.

The pin also supports I2C communication. Check its placement near ground. This ensures safe connections. Avoid overloads on this pin. Devices using encoder functions may connect. It powers peripherals like BMP180. Overload may harm modulation and voltage levels.

Communication Interface of Arduino Nano!

The Arduino Nano talks using SPI, I2C, and UART. Pins D0 and D1 send signals fast. For instance, their baud rate reaches 115200 bps. Pins A4 and A5 work at 400 kHz speeds.

Furthermore, pins D11, D12, and D13 transfer data at 10 Mbps. It adjusts the duty cycle for accurate signals. Hertz levels stay steady here. This setup boosts quantization for smooth data resolution.

The Arduino nano pinout helps connect right. Precision ensures clean signals. Demodulation manages data safely for sensors, logs, and devices. That way, nothing gets confused.

Troubleshooting And Debugging Arduino Nano Pinout Issues!

· Verify Connections

Check all links. Tolerance matters for pins D0-D13 components. Test A0-A7 inputs for stability. Inspect GND and 5V pins power. Verify the reset pin has 3.3V or 5V steady voltage. Check D3, D5, D6 PWM outputs. Measure 1k ohms impedance using a multimeter. Test continuity for ICSP header pins.

Cross-reference the wiring with an Arduino Nano pinout schematic. Avoid loose or floating wires causing drift. Inspect everything for linearity. Admittance changes indicate faulty circuits. Confirm secure connections. This ensures no failures.

· Check Power Supply

Test VCC output. Steady 5V or 3.3V means stability. Check RAW pin supports 6-12V range. Inspect GND for solid continuity. Use voltage regulators for input calibration. Confirm current draw stays below 40mA per pin. Micro-USB should hold 5V without hysteresis. Test DC barrel jack for safe supply.

Inspect reset voltage stability. Overvoltage harms microcontroller parts. I/O pin current limits avoid drift. Reliable power ensures Arduino Nano’s performance. This prevents any signal interruptions. Inspect everything against the Arduino Nano pinout for accuracy.

· Inspect Solder Joints

Examine every joint. Test for cracks and stability. Ensure cold solder joints don’t interrupt signals. Check SPI pins for clean connections. Verify A0-A7 pins stay within tolerance. Avoid short circuits. Fix flaws using flux for sensitivity. Power header joints must deliver reliable signals.

Verify oscillator connections maintain steady bandwidth. USB data pins D+, D- should communicate without issues. Inspect everything for signal linearity. Strong solder joints prevent malfunctions. This guarantees smooth communication.

· Test Components

Measure resistors. Confirm values match 220 ohms or 1k ohms. Check capacitors for linearity at 0.1µF or 10µF. Test crystal oscillator at 16MHz. Verify voltage regulator outputs stable 5V. Inspect MOSFET switches’ tolerance. Validate PWM currents on D3, D5, D6. Test LEDs blinking correctly.

Trace I2C signals for sensitivity on SCL and SDA lines. Confirm UART TX/RX data exchange. Use logic analyzers for analysis. Reliable components prevent errors. This ensures stability in circuits.

Comparing Arduino Nano To Other Arduino Boards!

· Difference Between Arduino UNO And Arduino Nano!

– Form Factor

The Nano’s size is small. It measures 18mm x 45mm. The UNO is 68.6mm x 53.4mm. This compact size fits tight spaces. Resistance ensures circuits remain stable. Nano has 30 header pins.

It supports 14 digital I/O pins. Its A6 and A7 pins boost use. Reluctance reduces with Nano’s flexible design. ATmega328P offers 16MHz speed. Capacitance aids data flow. Its mini-USB connector ensures seamless transitions. That helps Arduino Nano pinout suit small PCB layouts.

– USB Connector

The Nano uses mini-USB. It supports USB 2.0 for data at 12Mbps. Conductance manages signal flow. This boosts the upload speed. Its D+ and D- lines ease serial communication.

Unlike UNO’s Type-B, Nano’s mini-USB saves PCB space. The CH340 chip ensures smooth connectivity. Inductance stabilizes voltage delivery. It regulates between USB and external supplies. Arduino Nano pinout fits compact designs with this setup.

– Power Jack

The Nano lacks a DC jack. Its VIN pin accepts 6-12V inputs. That routes through AMS1117 for 5V output. Permittivity ensures low voltage drop. Its regulator supports USB or external power shifts.

A resettable fuse protects circuits. This design reduces saturation risks. Susceptance balances power delivery. Nano suits lightweight projects. Its optimized circuitry manages power reliably.

– Analog Pins

Nano has 8 analog pins. UNO has 6. Nano’s pins have 10-bit resolution. Reactance assists precise data flow. Its A6 and A7 pins boost options. Inputs tolerate up to 50mA.

Signals go through the multiplexer. This enables ADC conversion for data reading. Arduino Nano pinout supports real-time sensing tasks. That makes sensors work better. Permeability improves module compatibility.

· Difference Between Arduino Nano And Arduino Mega!

– Size

Nano measures 45mm x 18mm. Its PCB has 6 layers and is 1.6mm thick. Mega measures 101.52mm x 53.3mm. It uses a double-row pin layout. Nano fits tight spaces like wearables.

Mega works for robotics setups. Nano’s footprint suits small boards. Mega’s mounting holes simplify setups. Choose Nano for limited projects or Mega for expansive designs.

– I/O Pins

Nano offers 22 GPIO pins. It splits into 14 digital pins and 8 analog pins. Six digital pins support PWM. Mega supports 70 GPIO pins total. Its 54 digital pins include D0-D53.

Nano’s UART and SPI work with sensors. Mega’s expanded I/O fits shields. Arduino Nano pinout fits IoT. Mega supports larger systems easily.

– Memory

Nano uses 32KB Flash memory. It also includes 2KB SRAM and 1KB EEPROM. Mega holds 256KB Flash. It adds 8KB SRAM and 4KB EEPROM. Nano handles AVR code basics.

Mega works with larger data. Nano stores small logs. Mega handles algorithms better. For compact projects, Nano suffices. Larger tasks suit Mega’s memory map.

– USB Connector

Nano uses a Mini-B USB port. It allows 5V input. Mega has a Type-B USB port. Both enable serial communication. Nano fits wearables better. Mega suits industrial tasks.

Its larger connector stays stable. Nano’s USB handles firmware updates. Mega transfers high-frequency uploads. Choose Nano for compact designs. Mega suits large operations.

Understanding Arduino Nano’s Memory Types!

· Flash Memory

Flash stores data safely. Electrostatics help it stay stable. It holds 32 KB memory. Arduino Nano pinout uses 2 KB. The bootloader aids code uploads. Non-volatile storage keeps power-free data.

Its breadboard setup handles PWM tasks. Pins read inputs fast. Analog pins A0 to A7 process 0-5V signals. Digital pins handle LEDs or signals. Power pins give semiconductor support. It aids IoT systems.

· SRAM

SRAM stores short data. It’s volatile and clears fast. 2 KB enables operations. Pins D0-D13 manage signals. It supports electromagnetism protocols. Analog pins A0–A7 read 0–5V.

Arduino Nano pinout is efficient. Power pins supply modules. Bootloader supports ICSP headers. Jumper wires improve signal links. SRAM avoids system crashes.

· EEPROM

EEPROM saves small data. It keeps 1 KB storage. This memory stays. Pins A0–A7 read inputs. Digital pins handle conductors or outputs. Protocol pins extend electrodynamics memory.

It retains calibration values like passwords. Nano pins enable modules. EEPROM cycles handle memory long. Insulators secure stored configurations.

· Bootloader

The bootloader eases the loads. It uses 2 KB memory. USB connects code quickly. Pins RX, TX manage serial. ICSP headers improve firmware. Magnetism stabilizes operations. LED pins show status.

Power pins provide data paths. Bootloader aids Nano tasks. It smooths electrodynamics firmware setups.

| Memory Type | Size | Usage | Type | Write Cycles | Access Time | Retention |

| Flash Memory | 32 KB | Program Storage | Non-Volatile | 10,000+ | Moderate | 20+ Years |

| SRAM | 2 KB | Variables | Volatile | Unlimited | Fast | Not Applicable |

| EEPROM | 1 KB | Data Logs | Non-Volatile | 100,000+ | Slow | 100+ Years |

| Bootloader | 2 KB | Startup Tasks | Non-Volatile | 10,000+ | Moderate | 20+ Years |

Table on Understanding Arduino Nano’s Memory Types!

2D Model And Dimensions Of Arduino Nano!

· Length

The Arduino Nano is compact. Its dimensions are 45 mm long and 18 mm wide. It uses 30 male headers. These pins sit in two rows, spaced at 2.54 mm. This helps breadboard projects.

Its Mini-B USB connector gives power. The ATmega328P microcontroller, at 16 MHz, runs programs fast. It features 32 KB flash memory. Its 14 digital pins include PWM. There are 8 analog inputs for sensors. The length fits IoT systems.

· Width

The Nano’s width is 18 mm. It uses rows of 30 headers. The pitch is 2.54 mm. They connect to sensors or displays. Digital pins manage LEDs. Its PWM controls motors too. That VIN pin takes 7-12V.

The reset button works for errors. This compact size helps robotics. Its headers support MISO, SCK, and MOSI.

· Mounting Holes

The Nano lacks mounting holes. It uses headers instead. This 1.6 mm thick PCB stays strong. These headers secure with screws. Its FR4 material resists bending. That TQFP-32 package fits snugly.

Through-hole connections ensure strength. Pinouts align for precise Arduino nano pinout work. It’s still great for DIY.

· USB Connector

This Mini-B USB connection powers it. The CH340G chip supports serial. It’s rated at 480 Mbps speed. The LEDs show TX/RX. This helps programming debug codes. It handles USB 2.0 easily.

This makes every Arduino nano pinout clear. Its RST button stays useful. They work in IoT! You can consult HanuSEO as well for writing such blog for PCB/PCBA industry.

Conclusion

This saves time now. The Arduino Nano Pinout improves builds. It makes circuits smooth. Use it wisely. This avoids big errors. That brings better designs. Tools help your projects more. Visit PCBASIC now!