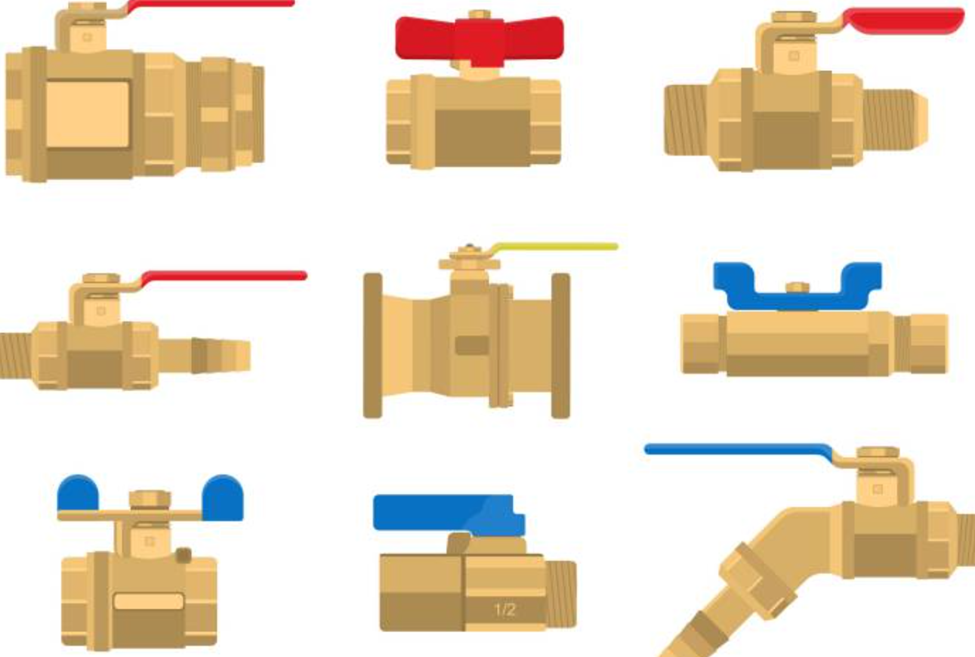

Brass valve use is wide, see it all around? You need a simple guide. So, this blog is for you. You will learn about types. Like, gate valves stop water flow. Also, globe valves adjust the water. Check valves keep the flow one way. As ball valves turn on or off fast. Since, each has its own special parts.

What Is A Brass Valve?

Brass valve controls airflow. A valve is a small, strong part. You can see one in bike tires. Usually, a valve core has a pin. A valve stem uses a spring. Presta valves have a nut, Schrader valves have a threaded body. Plus, valve caps protect from dirt. Tires require a certain PSI.PSI measures pressure. Typically, cars use 30-50 PSI. A bike might use 20-40 PSI. Some need 100 PSI.

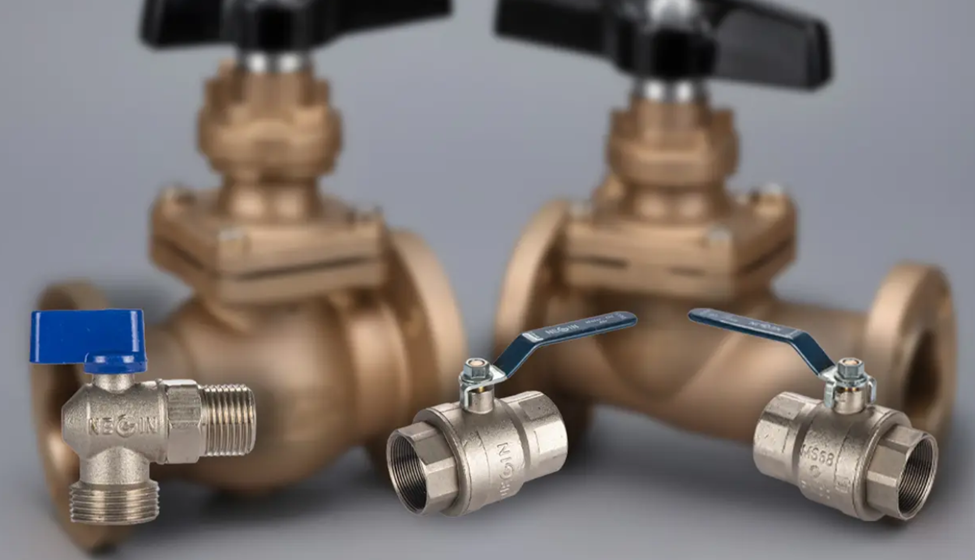

Types of Brass Valves!

· Gate Valves

Gate valves control water flow. Turning a handwheel closes the valve. Lowering a brass wedge stops flow. The handwheel has a 2-inch diameter. Gate moves 10 mm down. Thus, water at 25 PSI is stopped. These have a 1/2-inch body. While, threaded stem is 8 mm. Inlet and outlet ports are present.

Flow coefficients are 2.5 Cv. The operating temperature range is 32-250°F. The seal is a metal seat. Although, body is forged brass. The maximum torque is 5 Nm. Flow capacity is 5 GPM. Seals are PTFE. Body length is 2 inches. Brass valves have bonnet gaskets.

· Globe Valves

Globe valves regulate fluids. Adjusting flow is done with a handwheel. Also, stem moves a disc with a 1/4 turn. The pressure rating is 125 PSI. The handwheel diameter is 2.5 inches. Moreover, body is brass, and trim is bronze. Globe valves have 300 PSI cold working pressure. The size is 1 inch.

The port diameter is 1 inch. Further, temperature range is 30-200°F. Packing nut is brass. Seal is Teflon. The packing is PTFE. NPT connections are used. Body length is 3 inches. Flow capacity is 20 GPM.

· Check Valves

Check valves stop backflow. A hinged disc opens with forward flow. As a result, reverse flow closes it automatically at 5 PSI. The body length is 2.5 inches. Also, pressure rating is 200 PSI.

A brass body and disc are used. The hinge pin is stainless steel. Besides, seat is 3/4 inch. Disc lift is 10 mm. Spring force is 2 pounds. Their flow coefficient is 3.0 Cv. Y-pattern body is present. The temperature range is 0-180°F. But seal is metal-to-metal. Spring is Inconel.

· Ball Valves

Ball valves use a ball. Since ball has a hole, turning handle 90 degrees aligns or blocks the hole. The handle is 4 inches. Stem is 1/4 inch thick. Ball valves have a 600 PSI rating. Seats are PTFE, sealing at 15 PSI. The ball is chrome-plated brass. Consequently, flow rate is 15 GPM.

The temperature range is -20-450°F. So, body length is 3 inches. The ball diameter is 1 inch. Stem is blowout-proof. These are quarter-turn. Size range is 1/4 to 4 inches. Packing gland is adjustable. Brass valves are lever-operated.

· Butterfly Valves

Butterfly valves regulate large flows. You rotate a disc. Furthermore, body is 4 inches long. Disc is stainless steel. The stem is 1/2 inch thick. And, these have a 150 PSI rating. The seat is EPDM rubber.

The gearbox has a 10:1 ratio. Next, lug-style body is used. The shaft is 416 stainless steel. A 6-inch handwheel is used. The torque is 20 Nm. In addition, flow is 50 GPM. These have a 90-degree turn. They have 12 bolt holes. Temperature range is -30-250°F.

| Feature | Gate Valve | Globe Valve | Check Valve | Ball Valve | Butterfly Valve |

| Flow Control | On/Off | Throttling | One-Way | On/Off | On/Off/Throttle |

| Pressure Drop | Minimal | High | Moderate | Minimal | Low |

| Mechanism | Rising/Non-Rising | Plug/Disc | Swing/Lift/Piston | Rotating Ball | Disc |

| Size Range (in) | 0.5-60 | 0.5-16 | 0.5-24 | 0.25-12 | 1.5-60 |

| Temp Range (°C) | -200 to 800 | -200 to 450 | -200 to 400 | -200 to 250 | -50 to 400 |

| Actuation | Manual/Electric | Manual/Electric | Automatic | Manual/Electric | Manual/Electric |

Table on Types of Brass Valves!

Key Considerations When Choosing a Brass Valve!

· Application Needs

Application should be your first thought. Consider a lever handle for easy use. Brass valve controls water flow up to 200 PSI. You need to note a 1/2-inch inlet. While outlet size should match pipe. As a result, the stem, often brass, could have EPDM seals. Flow might be 5 GPM, but consequently, cycle life can be 300,000. Body is CA377, although, torque is 10 Nm.

· Industry Standards

Standards are crucial for safety in plumbing. Besides, you must confirm NSF/ANSI 61 for drinking water. Also, ISO 9001 shows quality, and API 6D is for pipelines. Thereafter, a 150# rating is common. Further, NACE MR0175 prevents corrosion. However, MSS SP-82 covers seats. Threads can be NPT, but a UL listing is good. Then, the packing meets EPA rules, so, bonnet could be a union type.

· Valve Sizing

Sizing ensures good water flow. Furthermore, you should check the Cv value, maybe 10. A 1-inch valve suits many jobs, yet, ensure proper connections. So, verify the flow coefficient. Next, actuator size matters, and port can be full. Then, a 2-way or 3-way may work. After, flange ends are ANSI 150, so, length is 100mm. Thus, select a ball type. As, bore is 25 mm.

· Pressure Ratings

Pressure is important to consider. A brass valve must handle your system’s maximum PSI. Typically, 600 WOG is common, meaning 600 PSI for water. Moreover, 150 PSI for steam is standard. Clearly, burst pressure is triple that. Next, seat material matters. Besides, the shell must be strong. Additionally, the body rating may be 900 PSI. Finally, check PN values, like PN16, so the gland holds.

· Temperature Ratings

Temperature must be considered for safety. Furthermore, you should know the maximum degrees Fahrenheit, perhaps 350°F. Though, minimum is vital, often -20°F. Also, O-rings should work. Then, the body must be right. Besides, parts expand. Next, stem packing is key, maybe graphite, but note the media, for, hot water. So, a cryogenic valve is for below -320°F, since they work safely.

What Are The Top Features of Brass Valve?

· Body Materials

Bodies are made of strong brass, a copper alloy CW617N. CuZn40Pb2 is used also for bodies, containing 38% zinc. You will find many parts inside the body. Parts use HPb57-3 brass having 57% copper, 3% lead. Forging, done at 800°F, uses a 500-ton press. C37700 brass has 60% copper, 2% lead. This alloy is machined, CW614N, containing 59% copper, is used, handling pressures up to 300 PSI. It can withstand 150.

· Stem Design

Stems in brass valves are blowout-proof. You should know, EPDM rubber O-rings, at 70 durometer, seal stems. The stem nut, made of chrome-plated CW614N brass. Moreover, PTFE Teflon stem seals withstand 450°F. Double O-rings help prevent leaks, using 1/4 turn operation.

Zinc plated steel handles, 2mm thick, operate stems. Furthermore, stems feature 15-micron nickel plating, torqued to 10 Nm. Precision machining ensures smooth operation, measuring 15mm in diameter.

· Disc Design

Discs are CW617N brass with 20 microns of chrome plating. Also, a ball valve has a round disc, a ball. The ball has a 1/2-inch port with a 0.2 Ra finish, measuring 25mm. A gate valve has a wedge disc. The disc, often 2mm thick, matches pipe size, like a 2-inch valve’s 50mm disc. While discs are full bore, they undergo 100 PSI pressure testing.

· Seat Materials

Seats in a Brass valve are made of PTFE, or Teflon. As, seats, 2mm thick, are die cut, rated for 400°F. Reinforced PTFE, with 15% glass fiber, handles 500 PSI. Seats seal the disc, using virgin PTFE. Chemically inert, seat diameters match disc size, like a 1/2-inch valve’s 13mm seat. But glass filled PTFE is gray, making seats replaceable.

· Seal Materials

Seals, like EPDM or Nitrile rubber O-rings, are 70 durometer. Gaskets, sealing body halves, use PTFE tape, 0.1mm thick, rated to 500°F. Graphite seals handle 850°F. Because packing, made of braided graphite, seals stems in rings 3mm thick. Spiral wound gaskets use 304 or 316 stainless steel with graphite filler. For, Viton fluoroelastomer rubber, 75 durometer, is used.

Brass Valve Installation and Maintenance!

- Installation Techniques: Use right tools like wrenches. Make sure the threads on the pipe match its size. You can hook a brass valve. Use Teflon tape to seal. Tighten nuts firmly. Check the inlet and outlet. The pressure should be right. The handle is very vital. Water should flow well. Inspect seals. The valve stem matters. A nut is key. The disc must align. Use a wrench. Temperature is crucial.

- Maintenance Procedures: Check for easy movement. You should inspect the stem. Lubricate it once a year. Tighten the nut a bit. Seals should not be torn. Check connections often. Measure flow rate. It must be correct. Look at O-rings. Clean any dirt. The seat needs care. Find cracks. Test pressure. Handle should be tight. Ensure the ball valve shuts.

- Leak Detection: Use soapy water. You will spot bubbles if there’s a leak. Check the stem. Inspect for any water. A gauge helps here. Low means a leak. Check joints. Listen for hissing. Use a special tool. Look at the nut. Check the seat. View the seal. Ensure no marks. Feel pipes. Brass valve should be dry. Tighten if you need to.

- Valve Repair: Turn off the water first. Then, use a wrench. Remove the packing nut. Inspect the stem. Also, check the seat. Clean all dirt. Use a small tool. Change old O-rings. Put on new tape. Tighten the nut. Check the handle. Test with some pressure. Ensure there are no issues. Look at connections. Make sure the disc fits.

- Valve Replacement: Shut off the main water. Drain the old pipes. Use the right tool. Remove the old one. Inspect for any damage. Pick a new valve. Ensure the size matches. Apply tape. You should connect the valve. Tighten it well. Check inlet, also outlet. Turn water on slowly. Check for leaks. Ensure easy use. Verify position. Check water flow rate.

Common Brass Valve Applications!

- Plumbing: Plumbing fixtures need the right parts for water flow. A durable brass valve is key. These often use a 1/2-inch connection. Your sink uses a 3/8-inch inlet. Also, a 1/4-turn handle is simple to use. Because the seat is PTFE material. A solid stem adds strength there. The body is brass.

- HVAC: Heating units need correct temperature control. You might find a 2-way zone valve. These have a 3/4-inch connection. Additionally, a 24V motor powers them. A Cv rating of 7.5 is typical. But some have a manual override lever. A 15-psi differential exists. The brass valve is a great fit.

- Industrial: Industries utilize many robust parts. Processes require managing high pressures. A 1-inch flange is crucial. Moreover, a threaded valve has 14 threads. The stem uses a 9/16-inch diameter. Its seat features a 2-inch orifice. Then, a hand wheel is 6 inches. The gland is graphite.

- Water: Water control requires tough parts. You can use large diameter valves. Some are ten inches wide. Because many operate at 150 psi. They have an epoxy coating. This is 10 mils thick. Most use a ductile iron disc. Also they have a Buna-N seat. A counterweight is present.

- Fluid: Fluid handling needs parts for flow. These valves allow for adjustments. The trim size may be 1/4 inch. Then, they feature a needle design. They use a 300 psi rating. The stem packing is Teflon. Further, you can see a locking nut. Some operate on 5 volts.

How To Choose the Right Brass Valve Supplier?

· Supplier Experience

Look at supplier history first. You need various parts always. Sizes must be 20 mm or 25 mm. Ratings can be 150 PSI, and 300 PSI. Check for a body of DZR CW602N. Choose stainless steel 304 for handles. Seats can be PTFE types. A 1/4 turn ball is vital. Seals are NBR, EPDM, FKM. Use ISO 9001. Working at -10°C is crucial. A stem of brass CW510L helps. Testing at 6 bar is key. Brass valve threads are key.

· Product Quality

Inspect products well, like a pro. Full bore is a good option. Stem must be blowout-proof. Consider the gate, globe styles. Size can be 1 inch or 1.5 inches. Body should be forged for quality. Pressure should resist 16 bar too. Brass can be CW614N and C84400. Plating must be top-notch. Check sandblasting or machining finish. Testing at 0.5 bar prevents leaks. Actuator’s torque is 5 Nm. The ASTM B584 is a standard.

· Customer Support

Great service is a major plus. Response time should be one day. One-year warranty is a need. Check for a 24/7 after-sale service. Ask for NPS 1/2-inch parts. Orders can be 100 or 10,000 pieces. Stopcock knowledge is good to have. Staff must guide you on loss. See if a PN16 valve works. A DN15 size might fit well. The team should grasp flow issues. Inquire about water hammer problems.

· Technical Assistance

Experts need to know valve details. They must know all thread types. Getting help with using is crucial. They should suggest good maintenance steps. Solving problems is also very essential. Plus, they explain the flow rate. You need advice on material choice. Picking the right valve size helps. Furthermore, knowing flanged end connections matters. Actuator choice is made easy. Lastly, safety factors are clearly explained by experts.

· Competitive Pricing

Prices should also be very fair. Ask for a single unit cost. You should get a bulk discount. Compare a 1-inch valve price. Verify model C37700 cost also. Also, check payment terms, like 30 days. Shipping cost matters for all orders. Check the minimum order rule. Factor in yearly, total use costs. Assess value for money spent. A brass valve is a good buy.

Recommendation: Choose BMAG Valves!

BMAG Valves is the best choice. They have 20-plus years of experience. Also, providing quality brass valves is their focus. Water meters meet high standards. DZR CW602N is used in products. BMAG is ISO9001:2015 certified. Custom solutions are offered by them. “BMAG” means reliability in valves. Further, the team supports clients well. Hence, they are best for waterworks.

FAQs!

What Is The Maximum Pressure Rating For Brass Valves?

A brass valve handles much force. Most work up to 200 PSI. Because some go to 600 PSI, check body markings. A 1/2-inch size is standard. Note stem, nut, also bonnet. Operating at higher temperatures needs lower pressures.

How Often Should Brass Valves Be Inspected?

Inspect yearly for your safety, looking for damage. Turn off water flow before starting. Examine the body joint afterward, seeking tight seals. You must check packing nuts, stopping stem leaks. Note the 150 WOG rating, using proper tools.

Can Brass Valves Be Used With Aggressive Chemicals?

Generally, chemicals harm the valve body since brass is copper, including zinc. Acids damage that, so check pH levels first. Anything below 7 is acidic, while high chlorine causes corrosion. A brass valve might not work here.

Conclusion

Brass valve use is now clear to you. You know many key factors. But pressure ratings are vital for picking. Plus, heat limits keep you safe. Then, good material makes valves last longer, so pick the right one. Next, right install is a must. After, check often for smooth work. For, help, see HanuSEO. There, you find real pros now.